Sustainable packaging: 5 ways to reduce emissions

January 8, 2026By Luke Millspaugh, ClimatePartner USA

Responsibility for packaging emissions is shifting upstream.

Extended Producer Responsibility (EPR) regulations such as Oregon’s Plastic Pollution and Recycling Modernization Act, are pushing producers to measure environmental impacts, demonstrate improvements, and rethink material choices.

At the same time, demand for sustainable packaging is rising from both businesses and consumers. Large brands including PepsiCo and Nike now require product-level carbon data from suppliers to inform procurement decisions. Consumers are also paying attention: nearly 40% report switching brands because a competitor offered more sustainable packaging.

But meaningful progress does not require reinventing your entire packaging strategy. With the right data and tools, companies can reduce emissions step by step while strengthening customer trust and competitiveness.

Five ways to reduce emissions in packaging

1. Calculating the Product Carbon Footprint

Every climate strategy starts with a baseline.

A Product Carbon Footprint (PCF) calculates the emissions associated with a packaging solution across its life cycle, from raw materials to production and distribution. Beyond just a single number, PCFs break emissions down by life cycle stage, making it clear where the biggest reduction opportunities lie.

For packaging producers, PCFs enable direct comparisons between materials and formats. For brand owners, they provide product-level data that is increasingly required by customers, retailers, and procurement teams.

Most importantly, PCFs turn sustainability from an abstract goal into a data-driven decision-making tool.

2. Switching to lower-carbon materials

Once hotspots are identified, material choice is often the strongest lever for decarbonization. Virgin, petroleum-based plastics and foams remain widely used due to cost and availability, but they are among the most carbon-intensive packaging inputs and are increasingly scrutinized by regulators and customers alike.

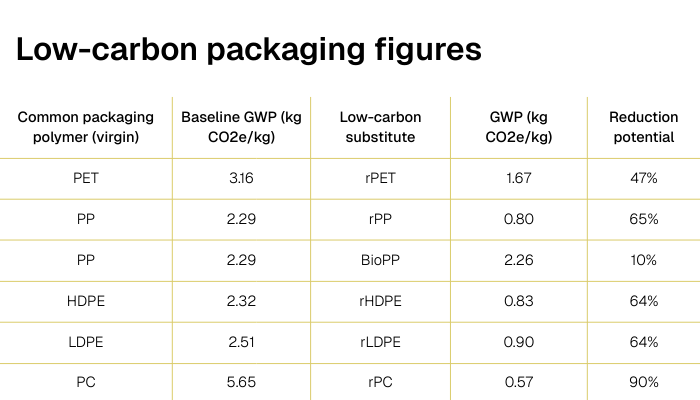

Many lower-carbon alternatives are already commercially viable. Recycled and bio-based polymers can often be introduced within existing packaging formats and supply chains, delivering immediate CO₂e savings while longer-term redesigns for reuse or recyclability are developed. In many cases, switching materials reduces packaging emissions by 40–90%.

Using ClimatePartner’s library of primary data-based emission factors and two decades of materials research, we’ve modeled the reduction potential of common plastic materials.

3. Transitioning to renewable energy

Energy use is major driver of emissions in packaging production, especially for electricity-intensive processes such as molding, extrusion, and forming.

For producers constrained by existing equipment or capital investments, renewable electricity offers one of the fastest and most scalable reduction options.

Through Energy Attribute Certificates (EACs), for instance, companies can source verified renewable electricity without changing utility providers or installing on-site generation. This approach immediately reduces scope 2 emissions by up to 100%. For brand owners, renewable energy procurement also supports scope 3 reductions by encouraging suppliers to decarbonize their operations.

4. Connecting purchases to verified climate action

Digital integrations allow emissions data to move from internal reporting into the customer journey. By linking transaction data to an already calculated PCF, API integrations can surface the emissions associated with a specific packaging format or product and offer customers the option to contribute an equivalent amount toward verified climate projects at checkout.

This creates a clear and credible connection between purchasing decisions and emissions impact, while keeping operational effort low. Automated, transaction-specific calculations and real-time booking of climate contributions improve data quality, reduce manual work, and connects climate action to sales.

5. Earning a sustainability certification

Climate action only creates business value when it’s communicated clearly and credibly. Packaging is often the first physical touchpoint between a product and its customer, making it a powerful channel for transparent sustainability communication.

Certification provides that credibility.

The ClimatePartner certified label is based on global carbon accounting standards and represents measurable action backed by data, reduction efforts, and verified impact. Each labeled product includes a unique climate-ID accessible via QR code or link, allowing stakeholders to explore emissions data, reduction measures, and supported climate projects. This transparency builds trust and turns packaging into a visible signal of climate leadership.

Sustainable packaging strategy

As packaging expectations continue to rise, producers and brand owners have a clear opportunity to turn emissions reduction into a strategic advantage.

By grounding decisions in product-level carbon data and applying practical, scalable solutions—from lower-carbon materials to renewable electricity—companies can achieve measurable progress today without waiting for full system redesigns.

When paired with transparent communication and credible certification, these actions not only reduce emissions but also strengthen customer trust, support procurement requirements, and position businesses ahead of a rapidly changing market.

Reach out today and talk to an expert on how you can reduce packaging emissions while increasing business value.