What does cradle-to-gate mean?

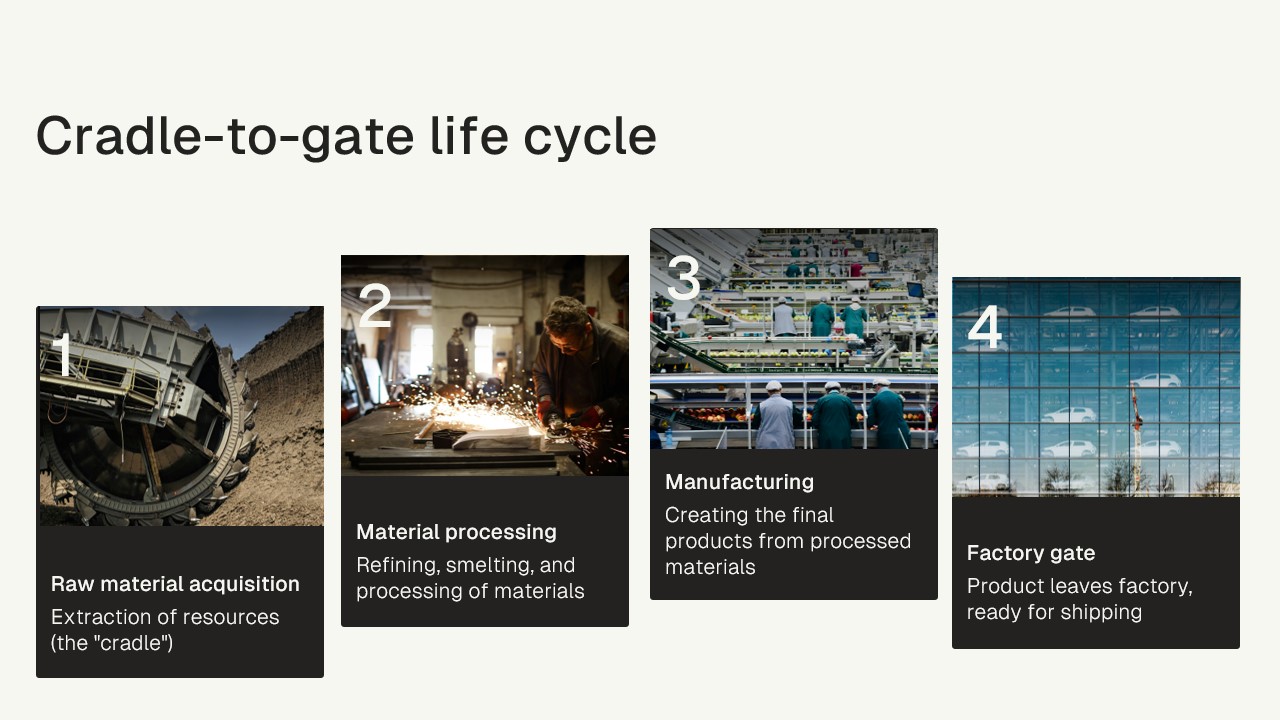

Cradle-to-gate refers to a life cycle assessment (LCA) boundary that covers a product’s journey from the “cradle” (raw material extraction) up to the point it leaves the production “gate” (the factory exit). It includes:

- Raw material acquisition and processing

- Manufacturing and assembly of the finished product

- Packaging and internal transport

The use phase of the product and its end-of-life disposal are omitted in a cradle-to-gate carbon footprint analysis. Cradle-to-grave includes this final stage while cradle-to-cradle replaces the grave with a recycling/re-use phase, which starts the LCA process over again.

Scope of a cradle-to-gate life cycle assessment

A cradle-to-gate LCA defines its system boundaries to include only the upstream and core production stages of a product’s life cycle. Cradle-to-gate emissions excludes the downstream stages:

- Product distribution to customers

- Consumer use phase (e.g., energy or water use)

- End-of-life disposal, recycling, or reuse

By confining the scope to “cradle → gate”, the LCA captures what is often called the embodied impacts or upfront carbon of the product. This system boundary is explicitly defined during the LCA’s goal and scope phase (per ISO 14040/14044 standards) to ensure clarity about what is included or left out of the analysis.

Cradle-to-gate vs. Cradle-to-grave vs. Cradle-to-cradle

Cradle-to-grave (full life cycle)

This scope includes every life cycle stage: raw materials, production, distribution, customer use, and end-of-life waste management; the product’s entire “life journey” is assessed for environmental impact. It reveals downstream impacts that cradle-to-gate misses. For instance, some products (like a cotton T-shirt) may generate the majority of their carbon footprint during the use phase (e.g. washing and drying the shirt) rather than in manufacturing.

Cradle-to-cradle (closed-loop recycling)

Cradle-to-cradle (C2C) is a special case of cradle-to-grave where the “grave” is replaced by recycling or repurposing, effectively creating a closed-loop life cycle. This concept, closely tied to the circular economy, ensures that waste from one life cycle becomes the “cradle” of another product’s life.

The C2C model distinguishes between two types of material flows:

- Technical cycle: These are non-biodegradable materials (like metals, polymers, and synthetic materials) designed to be recovered, reused, or remanufactured indefinitely without loss of quality, avoiding downcycling (where materials degrade over time).

- Biological cycle: These are biodegradable materials (such as natural fibres or food byproducts) that safely decompose and return to the environment without harming ecosystems.

Choosing the right LCA system boundary

Cradle-to-gate offers efficiency and speed, ideal for suppliers or companies starting with carbon assessments.

Cradle-to-grave unlocks a full impact picture, essential for regulatory reporting and science-based target setting.

Cradle-to-cradle shifts focus to sustainable design and reuse but demands a higher operational commitment.

Business benefits of cradle-to-gate PCFs

Sustainability efforts don’t just check an ESG box. When done right, product-level carbon data helps companies cut costs, reduce risk, and stay competitive in a changing market.

Credibly and transparently communicate a product’s impact

Cradle-to-gate assessments give businesses credible data to back up their claims whether it’s in investor reports, client pitches, or supplier contracts. It’s about proof, not PR.

Find waste and cut it

Product emissions assessments spotlight where companies are burning energy, wasting materials, or using costly resources. That insight helps them redesign products to save money and run leaner.

Stay ahead of regulations

A cradle-to-gate assessment aligned with standards like ISO 14067 or the GHG Protocol supports compliance with emerging disclosure requirements (e.g., CSRD, SBTi, or EU Digital Product Passport).

Win over buyers with data they can trust

B2B buyers increasingly expect carbon footprint data in tenders and procurement; verified numbers boost trust, support sales, and give companies an edge with customers who want low-emissions products.

Standards and guidelines for cradle-to-gate carbon footprints

Cradle-to-gate assessments are supported by internationally recognised standards that ensure data is credible, consistent, and actionable. Whether for building internal tools, publishing product footprints, or preparing for regulatory audits, aligning with these frameworks gives the results weight and helps future-proof reporting.

- ISO 14040/14044: Core LCA methodology and system boundary definition

- GHG Protocol Product Life Cycle Standard: Allows cradle-to-gate footprints but requires disclosure of the scope

- ISO 14067: Specific to product carbon footprints; permits cradle-to-gate if clearly labelled

Ready to go beyond the gate?

Cradle-to-gate is just the start. ClimatePartner’s Product Carbon Footprint (PCF) services help you:

- Deliver full cradle-to-grave assessments

- Identify use-phase and end-of-life hotspots

- Comply with CSRD, SBTi, ISO 14067, and more

- Design for circularity and carbon reduction

The sooner you start, the sooner you see results. Don't get left behind while your competitors quantify, optimise, and report their full impact.

Learn more about how calculating product carbon footprints and more in the ClimatePartner Academy!